Mechanical specifications:

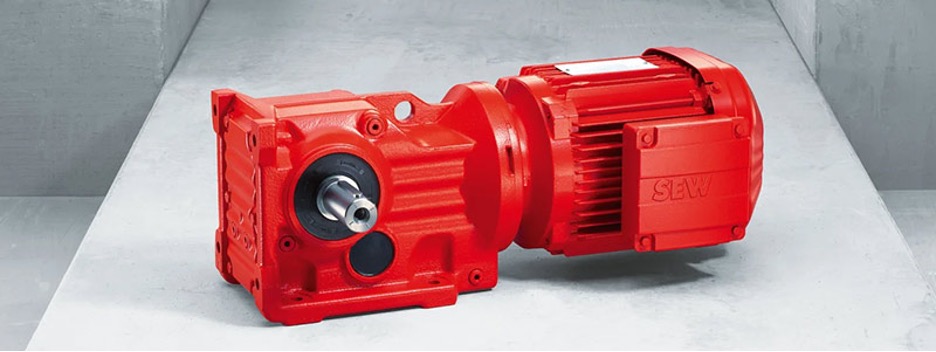

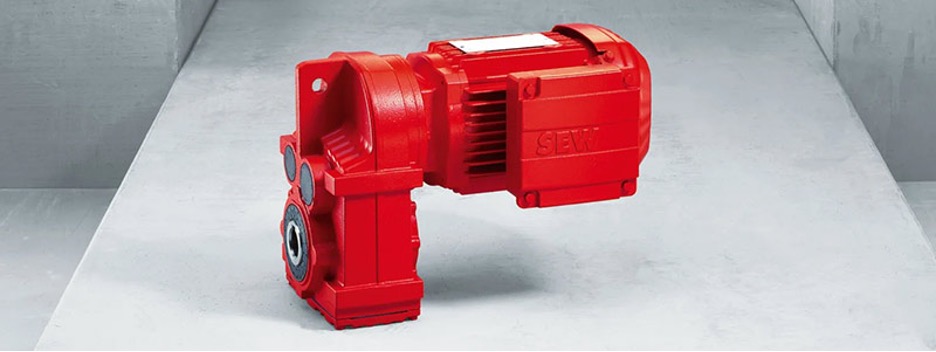

Longitudinal, transverse drives (gearbox)

Gearbox is one of the essential equipment in industrial cranes, especially overhead cranes, gantry cranes, semi-gantry cranes, jib cranes, monorail cranes and other types of workshop cranes. By converting the power produced by the engine into the driving force, the gearbox provides the necessary power to move the wheels to move the crane along the length and width of the cargo hall.

Overhead crane manufacturing companies design unique gears for their products. The gearbox of the overhead crane is designed according to the input power of the engine as well as the amount of power required to move the load.

In Farsi, it means gearbox. This equipment is placed in the path of industrial equipment after the engine, and with the mechanism inside the gearbox, the required torque of the device can be obtained by increasing and decreasing the ratio of the gears to each other. Therefore, the gearbox is a machine that is firstly used to transfer mechanical power from the power generating source to the consumer, and secondly to meet the torque and rotation speed required by the consumer, in such a way that the engine always rotates at the same speed and torque, and the gearbox has a duty based on the need. , change the output power and speed. So the gearbox is actually an intermediary between the energy source and the energy consumer, which establishes flexibility between the energy source and the energy consumer.

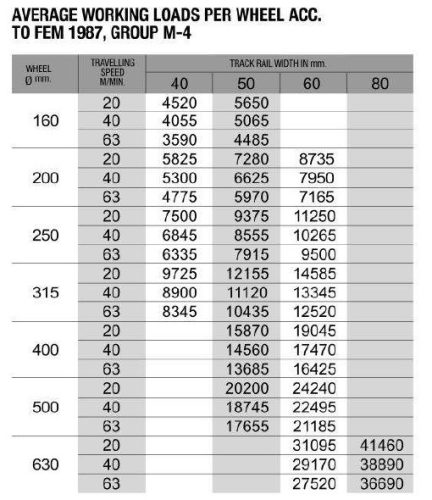

overhead crane wheel

Crane wheel is a very important part. Choosing it incorrectly will cause more friction. Due to the fact that the dead weight (crane structure and load weight) is finally introduced on the wheels; As a result, if you choose the wrong one, your crane will suffer serious damage. In the overhead crane, four wheels or eight wheels are used depending on the type of crane driver, two of which are driving and the other two are movable.

Type of crane wheel

When choosing the type of crane wheels, usually the first option to choose them is the crane working group. Because the working group of the crane determines the time and number of times it works. Nowadays, in the Iranian industry, overhead crane wheels are usually made of CK45, MO40, 3G70, and their selection is determined according to the work group and the type of overhead crane.

How to choose a wheel

Among other factors influencing the choice of overhead crane wheel, we can mention the crane rail; The choice of rails also determines the useful diameter of the crane wheel. Improper crane wheel selection may cause corrosion in your rail over time. that this process is costly for you.

Crane wheel dimensions

Crane wheel can be produced from size 120 (diameter or seat) to 500. For the past several years, sprockets have been the approved wheels for crane manufacturers. And they used that design in their cranes; Over time, due to wear and tear and replacement problems, the crane industry turned to hollow shaft wheels. Less friction and easy replacement conditions were among its good advantages.

roof crane hook

The hook in the overhead crane is an important and effective part of the crane's operational process. The hook is a part of the crane that is in direct contact with the cargo and is actually considered the final and final member of the lifting process in the crane, so it is of particular importance and paying attention to it, choosing the right type and material and being careful in its use and maintenance. It is considered very important.

The hook and its connected components are very important in overhead and industrial cranes. This piece, which is also called HOOK in English, is used as a means of carrying and lifting the load in all crane movements. Hooks have devils. Shaitanak plays the role of Hook's guarantor. If you don't use the hook of the overhead crane, it is possible for the load to come out of the hook. Therefore, it is recommended to use this device to maintain safety.

Crane S hook

The ceiling crane hook has Din15400/ISO/FEM standards, which consists of 5 working classes and from the heaviest to the lightest weight in 5 M/P groups. /S /T /V are abbreviated. The hook of the overhead crane has an important parameter called NR, which is referred to as HOOK NR in the standard tables. NR is inserted in the hook of the overhead crane as RSN. Through this parameter, we can measure the load carrying capacity of the hook. For example, the hook with RSN=0.8 in the ISO/FEM standard for the 1Am/M4 working group has the ability to lift a load of 1250 kg.

Tow wire

Steel rope (sim pixel)

The title of steel rope (simpixel) is used both for strong steel ropes that are used in mines and for delicate steel ropes that are used in bicycle brakes. . This title is used both for the fixed ropes that support the suspension bridges with tremendous force and for the ropes used in the elevators and cranes that are always moving. Therefore, steel ropes can have different types and different applications.

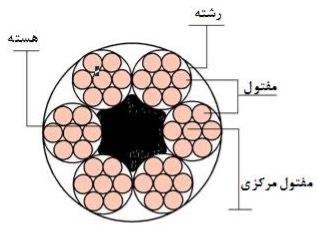

Steel rope in total length is a set of steel wires that form a single body. The steel rope includes a central part called the core, where several strands are twisted around it in a spiral. Each string is made up of several wires that are spirally placed around a central wire.

Steel rope according to the type of wire:

Generally, steel ropes are made from one of the following three types of primary materials:

1- Uncoated or non-galvanized steel wire: This type of wire is usually used for ropes in which the erosion factor plays a more important role in determining the useful life of the rope, and the rope is less It is exposed to factors that cause rust. When comparing the effects of wear and tear with the effects of rusting, it should be remembered that even an uncoated steel wire rope can be protected against rusting to some extent by adequate, proper lubrication at regular intervals.

2- Galvanized steel wire: This type of wire, which has a uniform coating of zinc, is resistant to rust due to sea water, air, humidity and other similar factors, so ropes Galvanized steel is used in fishing, poultry, and other industries.

3- Stainless steel wire: the ropes made of this type of wire are resistant to heat and rust up to 1050 degrees Celsius. They are used in the chemical, food and pharmaceutical industries and also have high resistance against the destructive effects of sea water.

tensile force of steel wire

Steel wire is produced with different tensile forces, according to the desired application. For the production of steel rope, the tensile force of the wire used will be in the following range:

Steel rope core

The core of the steel rope is the central part of the rope around which the strands are twisted. The role of the brain is to maintain the strings of the rope. Therefore, its diameter should be large enough to prevent contact between the strands when the rope is under load.

The core of steel rope can be fiber or steel:

A steel core may be an independent steel rope itself, in which case it is called an independent steel rope core. In the case of ropes with a diameter of less than 10 mm, the steel core will usually be a steel wire strand (IWRC). (WSC)

It consists of synthetic fibers or natural fibers. Although it is still common to use natural hemp in making steel fiber core rope (FC), synthetic fibers such as polypropylene are increasingly used as steel rope core.

It is necessary to mention that a steel core is used when the tensile strength and strength of the rope are more than other factors. While in the case of fiber core, the flexibility of the rope is more important than its tensile strength.

Steel ropes are divided into two types, normal and weak, as follows:

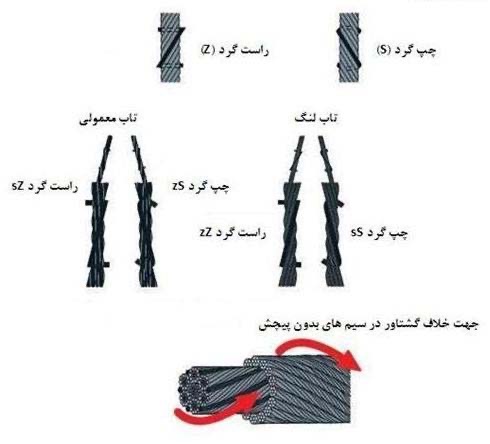

1- Ropes with normal warp: when the warp direction of the wires in a strand is opposite to the warp direction of the strands. This type of rope has a little tendency to unravel or get tangled and has more resistance against pressure, crushing and deformation. Instead, its resistance to wear and flexibility of the rope is less than the ropes with a weak swing.

2- Ropes with Lang swing: in the type of swing registered under the English name of John Lang, the direction of the wire in a string is the same as the direction of the strings in the rope. The resistance of ropes with a weak swing against wear is more than the ropes with a normal swing, but you must be careful when working with them so that the rope does not get tied or untied. Because this type of rope has a tendency to unravel, it is used in cases where both ends of the rope are restrained.

Generally, it is easier to work with ropes with normal swing and it is more commonly used, but in cases such as freight and passenger elevators, where more resistance to wear is desired, slack swing is preferred. be.

rounded right and left ropes

The term right round or left round is related to the direction of the strands in the rope. Right-round ropes are the most common type of ropes, and the direction of the twist to the left is indicated by Z in the figures below. In these forms, the swing to the right is marked with a letter.

Comparison of types of texture in steel ropes

Steel ropes usually have one of the four types of weave described below: in the weave type, in each strand of the rope, the number of wires in each row that is placed around the central wire:

p>1- Seale fabric is equal. The diameter of the wires of the outer row is more than the diameter of the wires of the inner row, but in each row, the diameter of all the wires is the same. Due to the thickness of the outer wires, these types of ropes have high abrasion resistance.

In the Warrington weave, each strand of rope in the outer row has thick and thin wires:

2- The texture of Warrington is one in the middle. Due to the combination of thick and thin wires in the outer row, Warrington ropes are more flexible than Seal ropes. In the filler weave, the diameter of the wires is the same in all rows. In the empty space between the wires, the outer row

3- Filler tissue and the inner row of thin wires are placed which are called filler. Filler ropes have more metal surface and have higher flexibility and abrasion resistance. In this type of weave, the diameter of all the wires forming each string is the same. Ropes with :

4- Standard fabric (Standard) Because of its high flexibility, standard fabric has a wide variety of applications in various industrial fields.

Steel rope oiling

Steel rope was lubricated in order to protect against rust and reduce friction between wires and strands during production. and on the other hand, all the wires forming a strand and all the strands forming the rope are smeared with suitable oil during weaving. The type of lubrication will be different according to the type of wire, the use of the rope and the characteristics of the place of use. During the useful life of the rope, its lubrication should continue at regular intervals in order to provide maximum protection against rust by replacing the oil lost due to use. internal wear and tear. It is better to lubricate the steel rope in a place where the strands are slightly separated, such as when the rope passes over the pulley wheel or is wrapped around the pulley. In this case, the oil is absorbed better. The oil used to lubricate the steel rope should easily penetrate the rope, cover its internal and external parts, not be washed with water, and protect the rope from rusting.

(Wear) and erosion (Fatigue (strong>) resistance to fatigue

Usually, fatigue resistance is at the opposite point of erosion resistance. A rope that is made up of a large number of thin wires is very flexible and has good resistance to fatigue, while a rope that is made up of a small number of thick wires will have a high resistance to erosion and abrasion.

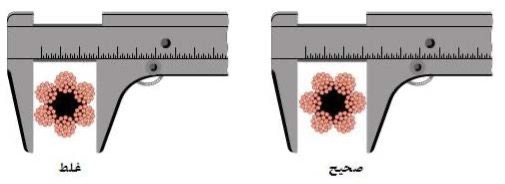

Measuring the diameter of steel rope

Measurement of the real diameter of a steel rope should be done at two points of the rope that are at least one meter apart. In each of these two points, the distance between the two ends of the opposite string should be measured with a caliper, and then this measurement should be repeated with two strings perpendicular to these two. The average of four measurements obtained in this way will be the actual diameter of the steel rope. This diameter is usually slightly different from the nominal diameter of the rope. According to American standards, the permissible limit of these differences will be from -1% to 4% for millimeter ropes and from zero to 5% for inch ropes.

How to store steel rope

The most suitable place to store steel ropes is dry and covered places where air flows easily

Be. The spools or coils should not be in contact with the ground or the wall. They can be placed on wooden pallets on the ground.

He took it and stored it. Stored steel ropes should be visited at regular intervals to ensure that there is no rusting.

They should be placed and if necessary, their lubrication should be renewed.

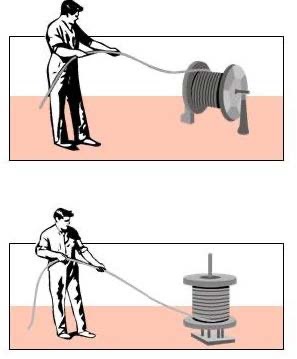

How to untie the steel rope from the reel and coil

When untying a steel rope, the following should be done to prevent it from getting tangled, which causes a significant reduction in the tensile strength of the rope:

1- Unwinding the coil: The coil can be opened as shown in the figure below by moving it on a smooth and level ground. Heavy coils can be placed on a rotating plate by rotating the rope plate with opened caution.

2- Opening from the reel: for this, the reel must be mounted on a base (rotary wheel) so that a shaft or a rod passes through the hole in the middle, so that by turning it Open the steel rope pulley in a straight line. In this case, you should be careful that the rope does not get knotted.

The standards used in the production process of overhead cranes, gantry cranes, jib cranes are as follows.

The design and calculations of our cranes are based on the European FEM standard, the American CMAA and the integration of local safety regulations and compliance with the following standard codes.

Welding of metal structures based on AWS D14.1, D1.1

Welding quality based on DIN 18800,

sheet 7

Crane design and construction based on DIN 15018

, sheet 1,2,3

Welding standard class DIN 8563, sheet 3

Hook construction (SINGLE DIN 15400

Hook construction (DOUBLE DIN 15400

Hook certificate DIN 15404

br />Electrical equipment VDE0100, VDE0113, IEC 60204-32

Electric motors IEC RECOMMENDATION 24-1,34-5,72-1

Gearbox design DIN 51150 ) ISO/DIS 6336/II-6336/

And the standards used in painting and cleaning the painted surface are done in accordance with the conditions of the installation site, the level of humidity, the corrosiveness of the environment and the client's request, using the products of reputable domestic companies with international approval.